Validation Services

Accelerate Your Time-to-Market with Expert Pharmaceutical Validation Services and Streamlined Regulatory Compliance

Take the first step toward achieving high-quality, compliant pharmaceutical products today.

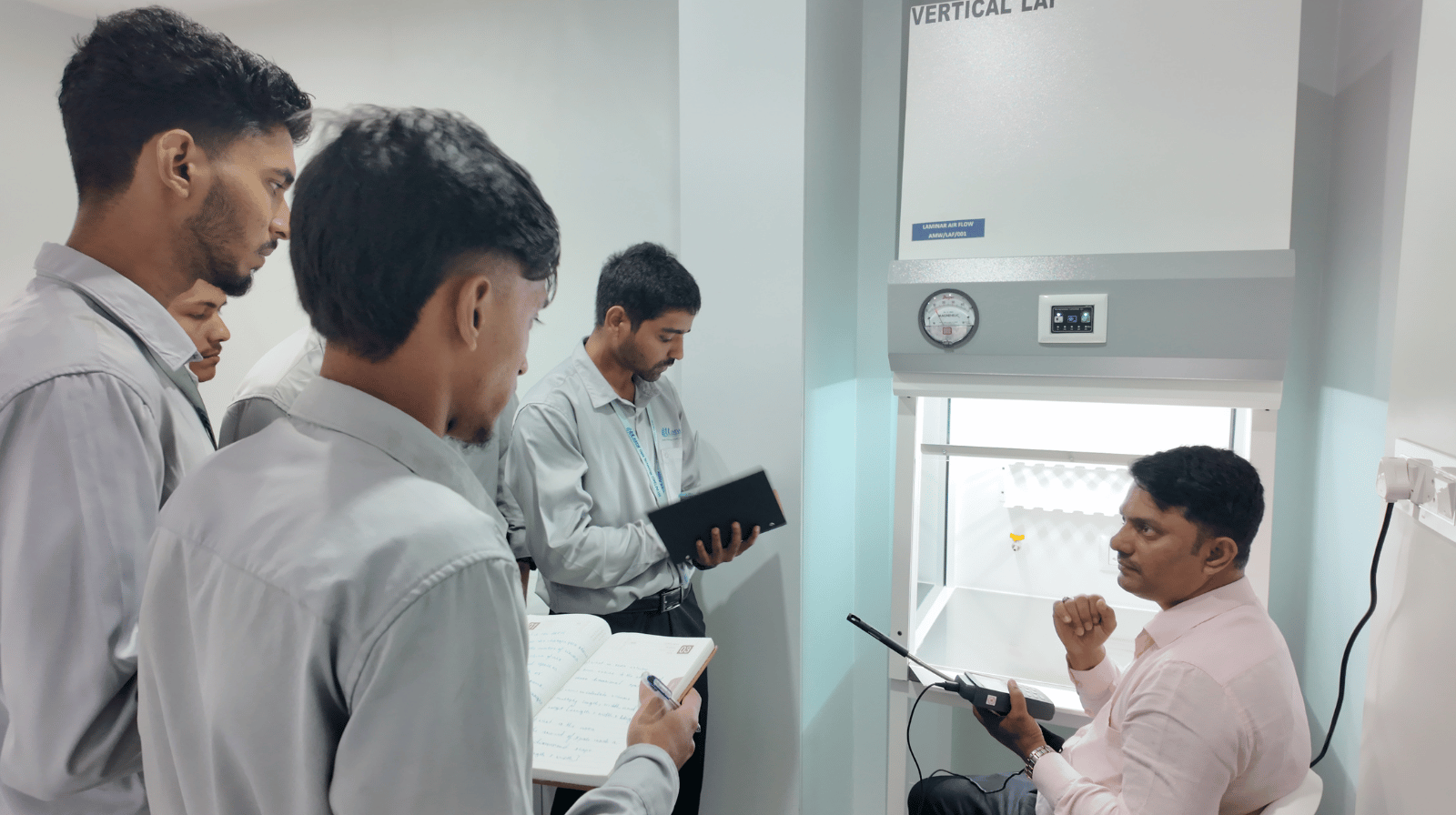

CQV services—Commissioning, Qualification, and Validation—are essential in the pharmaceutical industry to ensure that equipment, systems, and manufacturing processes function correctly and consistently produce high-quality products. We help you implement a rigorous CQV framework, ensuring your products meet required quality expectations and comply fully with regulatory standards.

Our Core Validation Services

Thermal Validation

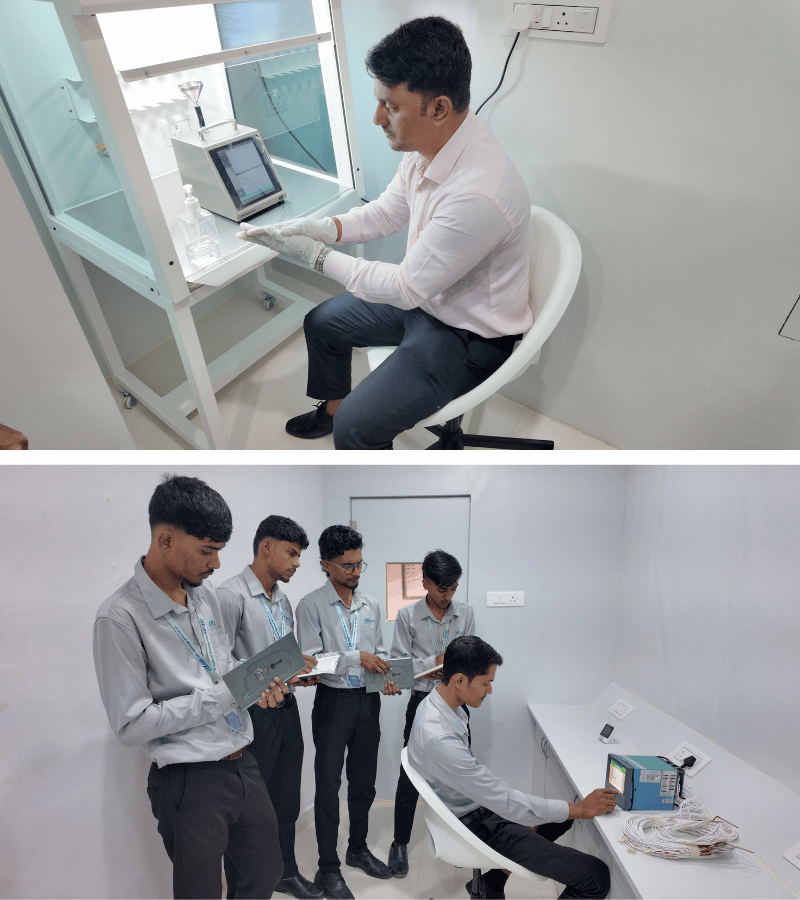

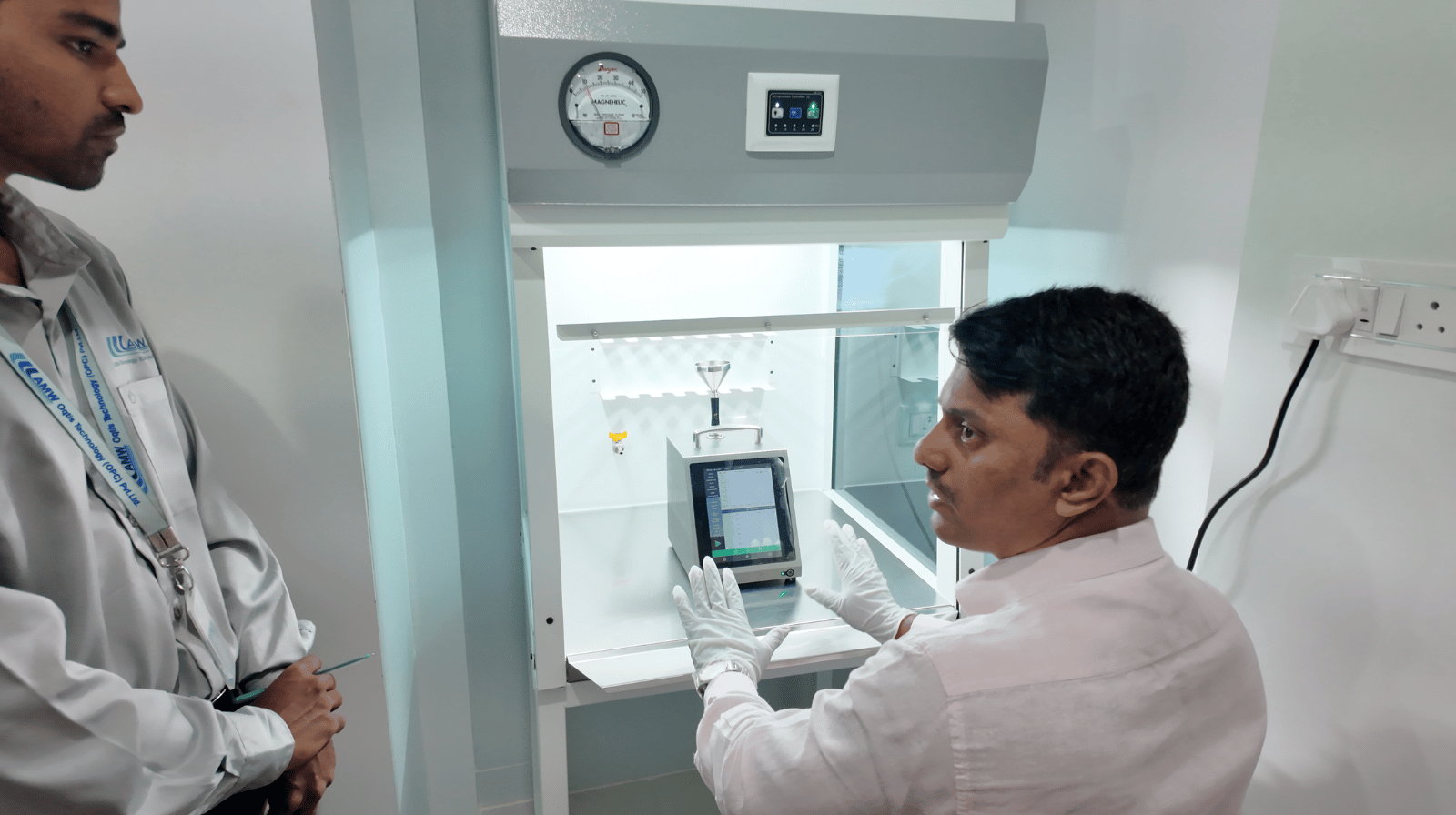

Cleanroom Validation

Computer System Validation (CSV)

Computer System Validation ensures that computer systems used for manufacturing, testing, and quality control meet their intended requirements and operate reliably. CSV is essential for maintaining data integrity, regulatory compliance, and system consistency across all digital operations.

Equipment Validation

Equipment validation ensures that all equipment used in the manufacturing, storage, and distribution of pharmaceutical products is properly qualified, calibrated, and functioning as intended. This process establishes documented evidence that the equipment consistently performs according to specifications, meets user requirements, and complies with regulatory standards.

Process Validation

Process validation involves qualifying the manufacturing process, equipment, and associated facilities to confirm they meet required standards for product quality, safety, and efficacy. It ensures the process delivers consistent and reproducible outcomes.

Cleaning Validation

Cleaning validation ensures that all manufacturing equipment is thoroughly cleaned to prevent cross-contamination, remove residual impurities, and maintain product purity. It verifies that cleaning procedures are robust, effective, and compliant with regulatory expectations.

Facility and Utility Validation

Facility and utility validation ensures that critical support systems—such as HVAC, purified water, compressed air, and electrical systems—meet required quality, safety, and performance standards. These validations confirm that the manufacturing environment consistently supports compliant and reliable operations.

Our Pharmaceutical Validation Process

Design Qualification (DQ)

Operational Qualification (OQ)

Installation Qualification (IQ)

Performance Qualification (PQ)

Continued Process Verification (CPV)

Importance of Validation Services

Compliance with regulatory requirements

Improved efficiency

Mitigation of risks

Building confidence in product quality

Ensuring Regulatory Compliance

We maintain strict compliance with globally recognized regulations and guidelines, including:

-

Good Manufacturing Practices (GMPs)

-

Good Laboratory Practices (GLPs)

-

Good Clinical Practices (GCPs)

-

International Council for Harmonisation (ICH) Guidelines

-

Food and Drug Administration (FDA) Regulations