Thermal Validation Service

What is Thermal Validation in the Pharma Industry?

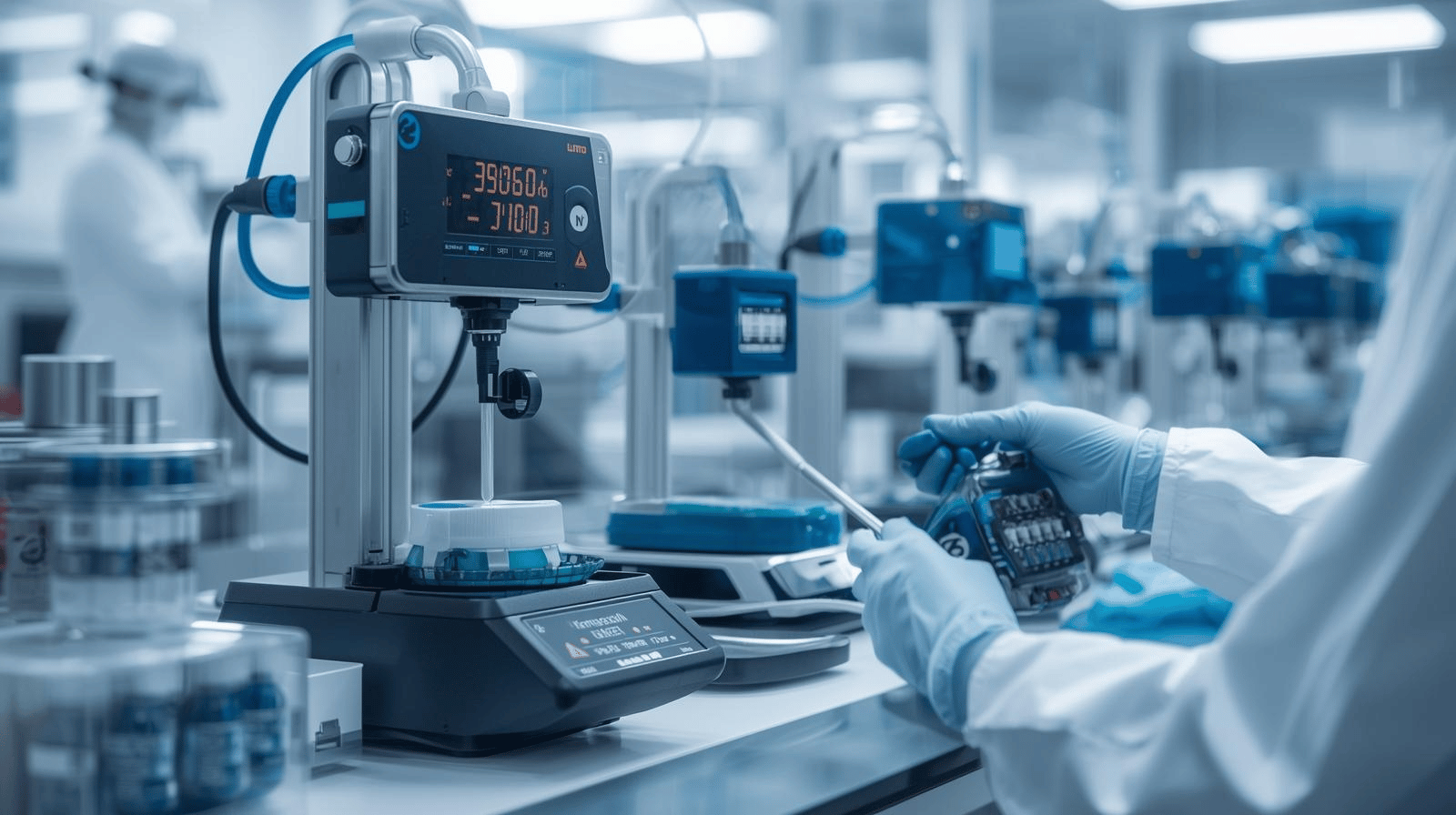

The thermal validation process uses data loggers, temperature probes, and other monitoring devices to measure and record temperature variations in both the equipment and the products being stored or transported. In the highly regulated pharmaceutical industry, maintaining strict temperature control is essential for compliance and product safety. Our thermal validation services help you meet regulatory requirements while protecting your products and preserving your reputation.

Our top thermal validation services include:

Equipment Qualification

Verifies that equipment used in temperature-sensitive processes is suitable for its intended purpose and capable of maintaining required temperature limits consistently and reliably.

Monitoring and Data Collection

Uses data loggers, temperature probes, and other monitoring devices to measure and record temperatures of equipment and products during storage, transportation, and production.

Data Analysis

Evaluates collected temperature data to confirm that the temperature-control system operates within the required range and maintains consistent performance over time.

Documentation and Reporting

Records all thermal validation results, documents any deviations or issues identified, and prepares comprehensive reports summarizing findings and compliance status.

Re-Validation

Conducts routine re-evaluation of equipment and processes to ensure continued compliance with regulatory requirements and ongoing assurance of product quality.

Compliances

In India, thermal validation services in the pharmaceutical industry are regulated by the Central Drugs Standard Control Organization (CDSCO). To ensure product safety, regulatory compliance, and operational reliability, the following key standards and guidelines must be followed:

-

Good Manufacturing Practices (GMP)

-

Good Documentation Practices (GDP)

-

World Health Organization (WHO) Guidelines

-

International Organization for Standardization (ISO)

-

International Conference on Harmonisation (ICH) Guidelines

-

Food and Drug Administration (FDA) – 21 CFR Part 11 Compliance

-

ISO 9001 & ISO 45001 Standards

-

Occupational Safety & Health Administration (OSHA) Requirements

-

EN 285 (European Standards for Sterilization)

-

Parenteral Drug Association (PDA) Guidelines

-

International Society for Pharmaceutical Engineering (ISPE) Guidance

USPs

Expertise

Compliance

Quality assurance

Efficient processes

Customizable solutions

Ongoing support

Industries We Serve

Thermal validation services are essential across multiple industries that manage temperature-sensitive products, processes, or environments. Our expertise supports a wide range of sectors, ensuring quality, safety, and regulatory compliance.

Pharmaceutical Industry

Pharmaceutical companies rely on thermal validation to maintain the quality, safety, and efficacy of temperature-sensitive products such as vaccines, biologics, and medications.

Biotech Industry

Biotechnology companies require thermal validation to preserve the stability of sensitive materials like cell lines, biologics, reagents, and vaccines.

Food and Beverage Industry

Thermal validation ensures the safety, freshness, and quality of dairy products, meat, produce, and other temperature-sensitive food items.

Chemical Industry

Chemical manufacturers depend on thermal validation to safeguard the quality and safe handling of temperature-sensitive substances, including hazardous materials, flammables, and refrigerants.

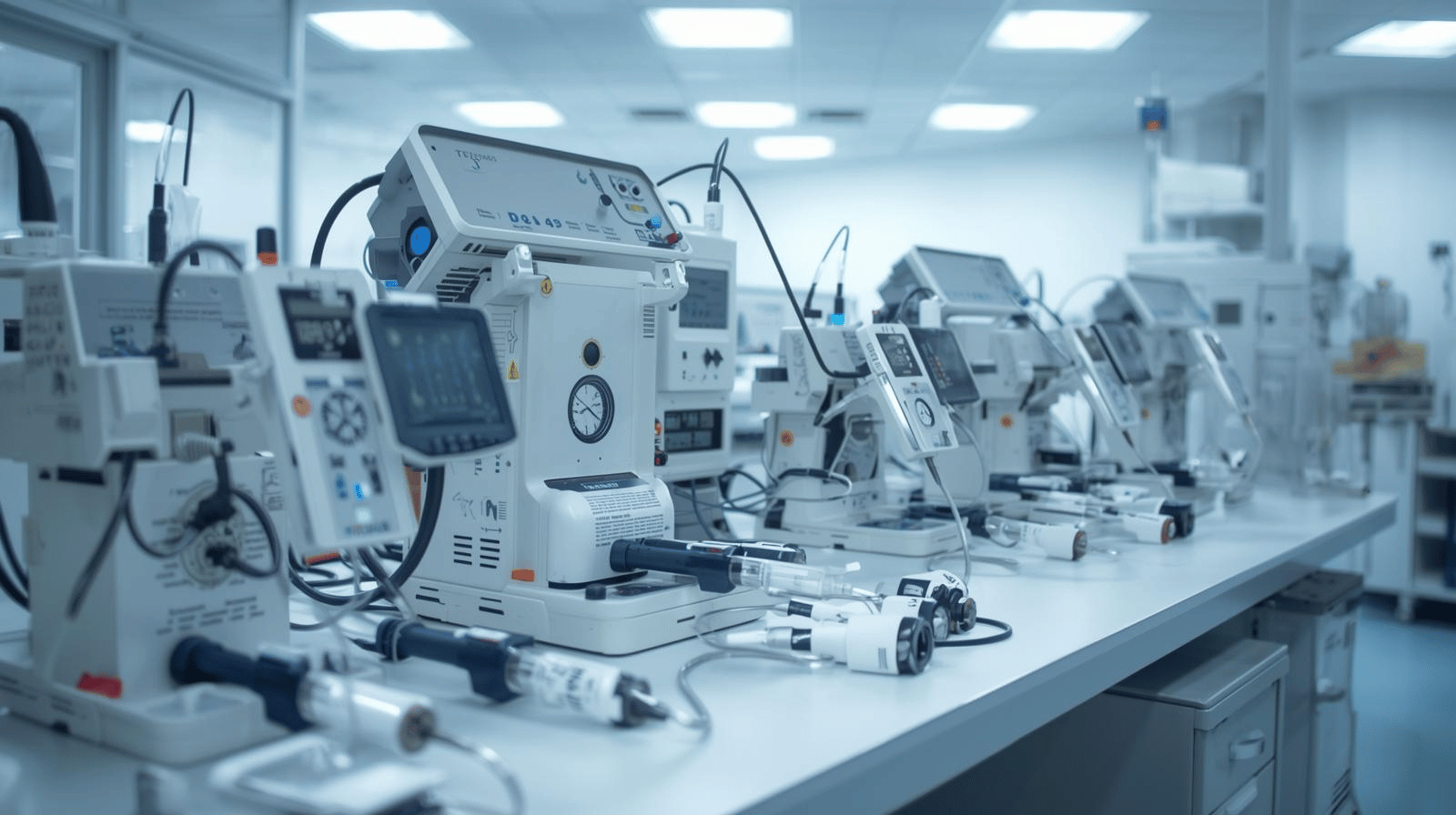

Medical Device Industry

Medical device companies use thermal validation to ensure the safety and functionality of temperature-sensitive devices such as implantables, surgical tools, and diagnostic equipment.

Life Sciences Industry

Life sciences organizations require thermal validation to maintain the stability and integrity of lab reagents, biological samples, and research specimens.

Logistics and Supply Chain Industry

Logistics providers and supply chain operators rely on thermal validation to ensure proper temperature control and product preservation during storage, transport, and distribution.