Calibration Services

High-Precision Calibration Services for Pharmaceutical Operations

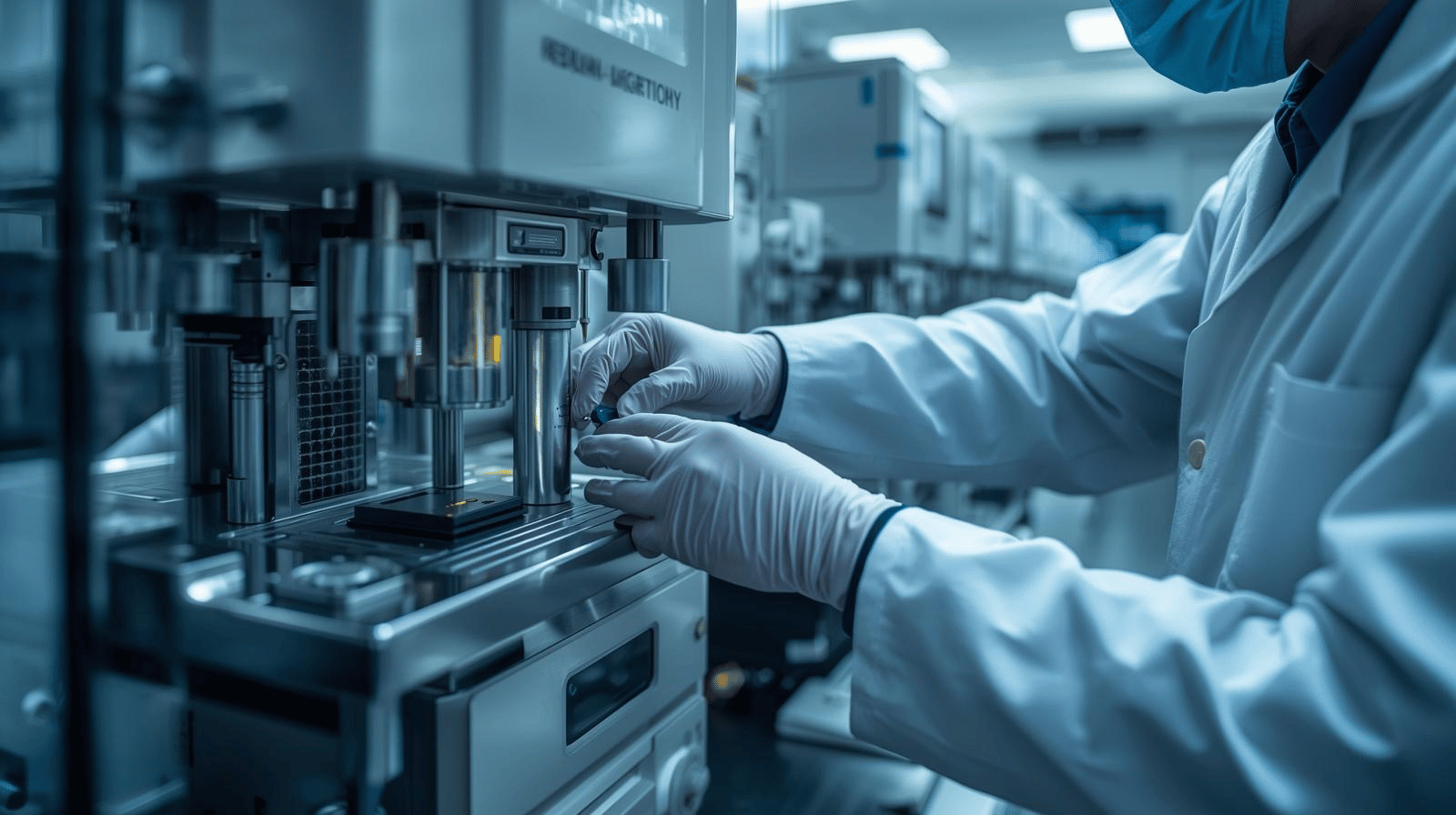

Our experts use state-of-the-art technology and stringent quality control procedures to deliver calibration services that are both accurate and reliable, consistently meeting and exceeding industry standards. We understand the critical importance of precise measurements in temperature-sensitive pharmaceutical processes, and our skilled technicians ensure that every calibration supports optimal performance and regulatory compliance.

Whether you require routine maintenance, emergency assistance, or tailored calibration solutions, we are here to help.

Contact us today to learn how we can help you achieve the highest levels of precision and accuracy in your pharmaceutical operations.

Powered by NABL Standards

Backed by a NABL-accredited calibration laboratory operating in accordance with ISO 17025 requirements, AMW Oqtis Technologies (OPC) Private Limited delivers standardized and highly reliable industrial calibration services. We specialize in maintaining instrument accuracy at the highest level, supporting the integrity of critical manufacturing processes across pharmaceutical environments.

Our Accreditation & Expertise

AMW Oqtis Technologies (OPC) Private Limited is an ISO 9001:2015 certified, cGMP-compliant private limited company providing end-to-end CQV services, including pharmaceutical validation, calibration, and preventive wellness solutions. Our commitment to quality and regulatory excellence makes us a trusted partner for consistent, compliant, and audit-ready services.

Our Approach towards calibration

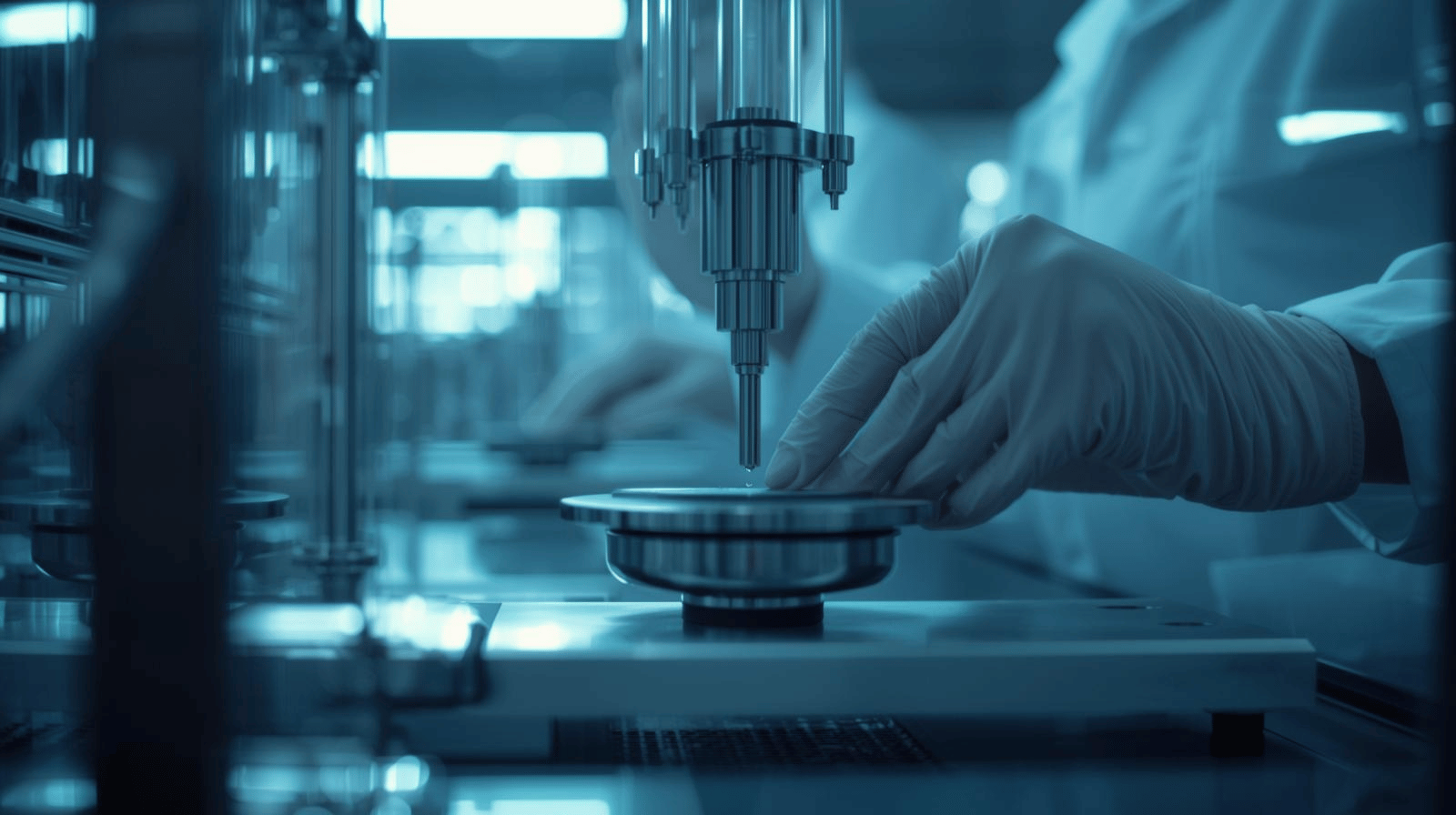

Identify the instrument to be calibrated and establish a suitable calibration schedule.

- Select appropriate calibration standards and reference materials traceable to national or international standards.

- Adjust the instrument to ensure it operates within the required tolerances and performance specifications.

- Record all calibration results and compare them against predefined acceptance criteria to verify accuracy.

- Generate a calibration certificate or report documenting results, deviations, and final status—essential for compliance, traceability, and audit readiness.

- Thermal Validation & Calibration Services

We Offer - We provide a comprehensive range of calibration services tailored to the needs of the pharmaceutical industry, including:

Mechanical Calibration and Thermal Calibration

Our experienced technicians use state-of-the-art equipment and proven techniques to deliver exceptional precision and accuracy. Our strong commitment to quality, compliance, and customer satisfaction sets us apart, ensuring your instruments consistently perform at the highest standards required for pharmaceutical operations.

Mechanical Calibration

Both mechanical calibration and thermal calibration are vital components of a comprehensive calibration program in the pharmaceutical industry. Together, they ensure that temperature-sensitive products are stored, transported, and processed in full compliance with regulatory requirements and established industry standards.

Thermal Calibration

Both mechanical calibration and thermal calibration are essential components of a comprehensive calibration program in the pharmaceutical industry, and are critical for ensuring that temperature-sensitive products are stored, transported, and processed in a manner that meets regulatory requirements and industry standards.

Why Choose Our Calibration Service?

Quality and Precision

Customer Satisfaction

Comprehensive services

Regulatory Compliance

Experience and Expertise

Timely and Efficient Service

Regulatory Compliances

As calibration service providers, we comply with a wide range of regulations and standards to ensure the highest level of accuracy, quality, and reliability in every calibration activity. These regulations guide our processes, documentation, and technical practices, ensuring full alignment with industry and regulatory expectations.

Key Regulations and Standards We Follow

21 CFR Part 11

Defines the requirements for electronic records and electronic signatures in the pharmaceutical industry. It governs the electronic systems used to store, retrieve, and process calibration data to ensure integrity and authenticity.

cGMP (Current Good Manufacturing Practice)

Establishes minimum standards for drug manufacturing, packaging, labeling, storage, and distribution. It also applies to the calibration and maintenance of equipment used in pharmaceutical processes.

ISO 17025

An international standard that outlines the general competence requirements for testing and calibration laboratories. It serves as the foundation for accreditation and ensures technical proficiency and reliable calibration results.

GLP (Good Laboratory Practice)

Provides standards for conducting non-clinical laboratory studies. It also applies to calibration service providers involved in testing, instrumentation, and method validation for pharmaceutical products.

GDP (Good Documentation Practices)

Ensures that all calibration-related documentation is accurate, traceable, legible, and compliant with regulatory expectations, supporting audits and long-term data integrity.